Polytunnel Cover Fixing Methods

There are a couple of different methods for fixing and tensioning your polythene polytunnel cover down to the ground. The first and most usually used is the trench method. This can be used where you are working on soft ground and are planning on burying the surplus polythene to tension and secure it to the ground.

The second method is by using a base rail to attach and weight the polythene. This can be quicker and easier, particularly where the ground is very hard and difficult to dig.

To help choose which method is best for you, read on.

Trench Method

This method is available for those constructing their own tunnel. The trench needs to be approx. 150mm wide and 50cm deep. It needs to run down both sides of the tunnel and into the door frame timber at the ends. The removed earth is placed back into the trench as per instructions and the weight of the earth holds the polyethene in place.

The trench method is suitable for all polytunnels (up to and including 24ft wide) constructed on a soil base.

Base Rail Method

This involves clamping a 50mm x 100mm timber rail at ground level to the ground tubes. 2 types of batten are supplied to enable the polythene to be rolled and nailed to the rail (nails not supplied).

In our experience, the greater the length of the polytunnel or when digging conditions are difficult, base rails are a simpler option. Base rails also have the advantage of being adjustable to allow for cover tensioning, therefore guaranteeing a drum tight polytunnel cover.

If base rails are used, it is necessary to use Anchor Plates to secure the steel polytunnel frame into the ground to prevent it lifting, even in the most severe weather conditions.

Even when using base rails, burying any surplus polythene ensures the base of the polytunnel is sealed against pests and draughts.

Polytunnel Foundation Methods

Your polytunnel needs to be firmly secured to the ground, especially if you’re setting it up on a slope.

It is not too difficult to construct a polytunnel, but it’s also not a task that you should take lightly. You need to secure your structure so that it will endure weather conditions and last the test of time. Some people may compare it to putting up a tent, but it definitely needs to be more firmly secured than that.

At Five Star Polytunnels, we have three options available for securing your polytunnel to the ground. Ground Tubes (also sometimes known as foundation tubes) are included in our kits as standard and can be driven into the ground (if the polythene is to be trenched) alternatively you can use Anchor Plates. If you have a solid base of concrete or timber then Base Plates will be required to fix it to your base.

Ground Tubes (For Soil)

Ground Tubes are included as standard as part of our polytunnel kits. We recommend that the Ground Tubes are concreted into the ground, whatever size tunnel you choose and whether you are using a base rail kit or trenching your polythene. The ground tubes are sometimes referred to as Foundation Tubes.

The ground tubes are the foundation for your tunnel and slide inside your tunnel hoop. At Five Star Polytunnnels, we believe that the ground tubes need to be made from thicker steel than the hoop. After all they are in contact with more water than the hoop and need to withstand a higher chance of rusting. There is little point of the hoops outlasting the ground tubes!

As an alternative to Anchor Plates the ground tubes can be set in concrete.

Anchor Plates (For Soil)

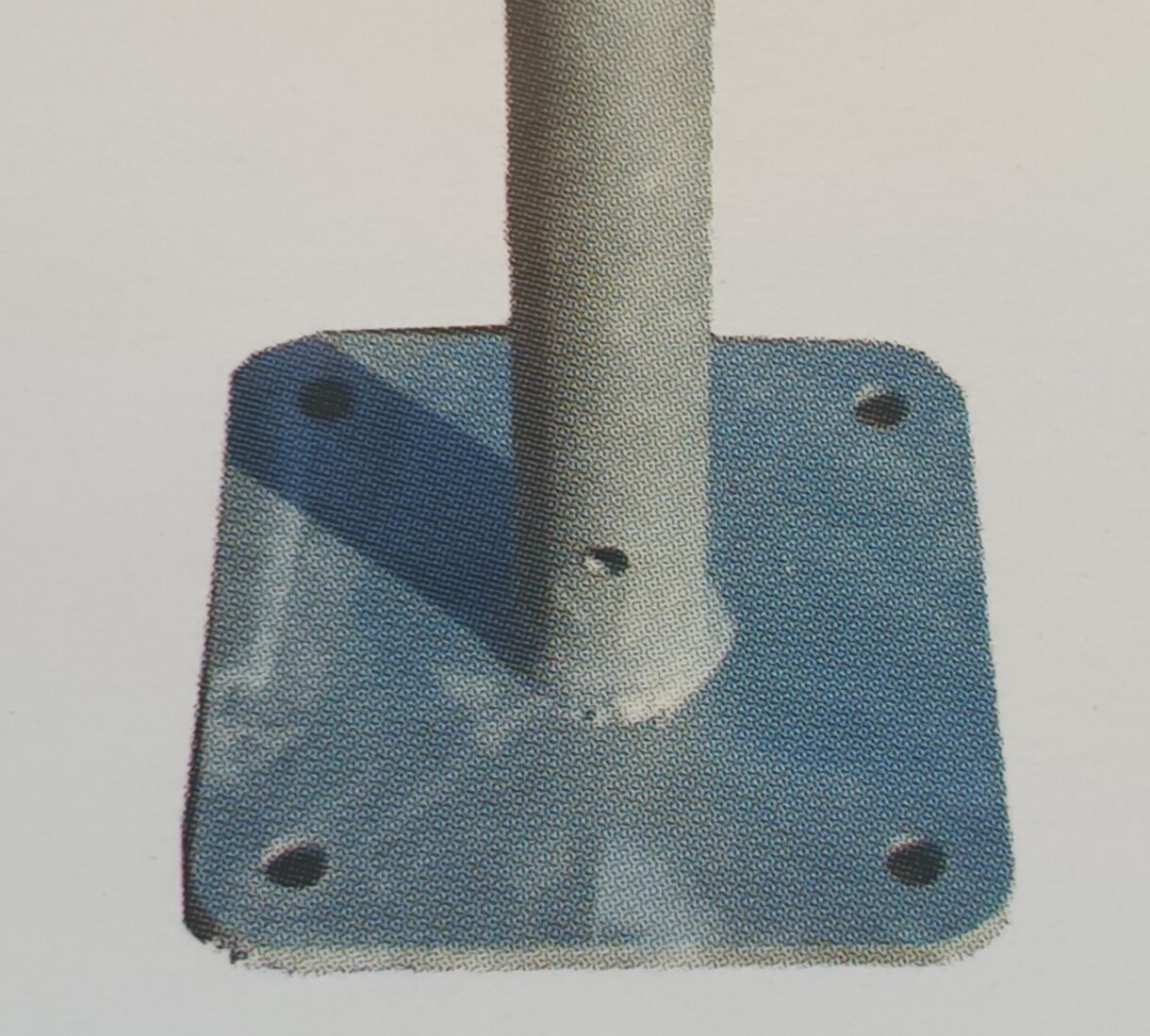

Anchor Plates are an alternative to concreting in ground tubes into soft ground, and are used to hold or anchor each ground tube in the soil.

Five Star Polytunnels supply a square heavy duty metal anchor plate with two fixings for each ground tube. Each ground tube has to have an anchor plate. The ground tube goes through the centre of the anchor plate and is fixed in place with clips either side, a few inches above the lower end of the ground tube. Each ground tube with its own anchor plate is installed at the required equidistant intervals.

We sell them in two different sizes depending on the size of your polytunnel.

Base Plates (Hardstanding e.g Timber or Concrete base)

Base Plates are chosen for a concrete or solid timber base i.e. where no soil is being used.

The plate is positioned on each hoop end, so ground tubes are not required.

They are supplied with four concrete fixing screws and are available in four different sizes (25mm, 32mm, 50mm and 60mm tubing) to suit your hoops.

A Base Rail is used to hold the polythene all round the polytunnel. The base rail comprises tannalised timber and battens.

You need two base plates for each hoop. For example if your polytunnel has 6 hoops you will need to purchase 12 base plate sets.

| Number of Hoops | Base Plates Required |

|---|---|

| 3 | 6 |

| 4 | 8 |

| 5 | 10 |

| 6 | 12 |

| 7 | 14 |

| 8 | 16 |

| 9 | 18 |

| 10 | 20 |

| 11 | 22 |